Metal container

production lines

BODYMAKER

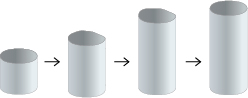

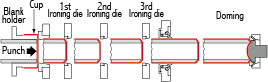

The cups become tall and thin-walled seamless cylindrical metal container by deep drawn and ironed process.

The bodymaker reduces the container diameter by the re-draw process and creates the tall and thin side wall by multiple ironing processes.

The wall thickness of the metal beverage cans is less than 0.1 mm and variation in thickness must be kept to a few microns.

The container diameter is between 50 and 70mm, the maximum height is 240mm, and the throughput is 400 products per minute. The accurate motion control technology by Sankyo is crucial for synchronizing the cup feeder and punch stroke mechanism. We are also considering ways to apply this specialized equipment for making large diameter and height cylindrical battery cases for large electric vehicles and energy storage devices.

Hypocycloid drive